-

Loader/Unloader (various development equipment)

Automatically supplies and stores workpieces to processing equipment, inspection equipment, etc.

Just by pressing the start button once, the system automatically performs everything from feeding to storing, thereby increasing work efficiency and reducing manpower at the work site. -

X-ray inspection equipment (various development equipment)

Equipment that takes 360-degree X-ray images (radiography) of an object and inspects its internal state without destroying it

-

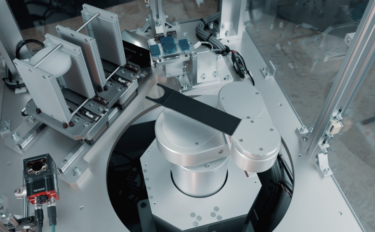

Chip aligner

Automatically transfers and aligns 0.5 mm chips.

Only the specified side of the chip is detected during pick-up.

After pickup, position correction, accuracy correction, color identification, and target chip search are performed.

The chips are then aligned at equal pitch intervals. -

substrate divider.

This is an automatic divider for ceramic substrates for micro chip resistors (0603, 0402mm).

High quality division is possible by reproducing human-like movements as if the chips were divided by human hands. -

Screen Printing Machine

We have shipped more than 200 units of screen-printers

We offer a variety of high-precision printing systems that meet customer needs in the field of small-sized precision printing, ranging from semi-automatic printing machines for prototype development to fully automatic printing systems with pattern recognition for production use, by incorporating various unique technologies based on high rigidity, including the center positioning mechanism that we developed in 1988, a world first. We offer a variety of high-precision printing systems to meet customers’ needs in the field of small precision printing.

Our screen printers are capable of printing on green sheets such as LTCC, and versatile printing on solar cells, glass substrates, printed circuit boards, small electronic components, etc. -

Defective inspection machine (various development equipment)

Measuring the current and voltage of elements, this device automatically laser-marks elements that do not meet the threshold values. Not only does the system judge if elements are GOOD / POOR by marking inspection, it can automatically acquire and manage measurement results.