Promotion Movie

Optical System Lineup

Fixed optical system, Galvano optical system

Production records

Our company has a wealth of experience in the development and manufacturing of laser processing machines for fine and precision applications, as well as in the mass production of laser processing equipment. In particular, we have installed over 300 laser processing machines for chip resistors made from alumina ceramics. With more than 20 years of knowledge and experience in laser processing, we can propose optical systems and oscillators that meet the material and processing requirements.

| For Alumina Ceramics (Chip Resistor Industry) | 310 units (No. 1 in domestic installations in the chip resistor industry) |

|---|---|

| For Patterning (Solar Cell Industry) | 44 units(Has a track record of installations with the top 3 domestic thin-film solar cell manufacturers) |

| For GaN, Glass, Sapphire, SiC (SD/LLO/Special Processing Applications) | 80 units (Delivered to the glass manufacturing industry for smartphone camera modules) |

What is a Laser Scriber?

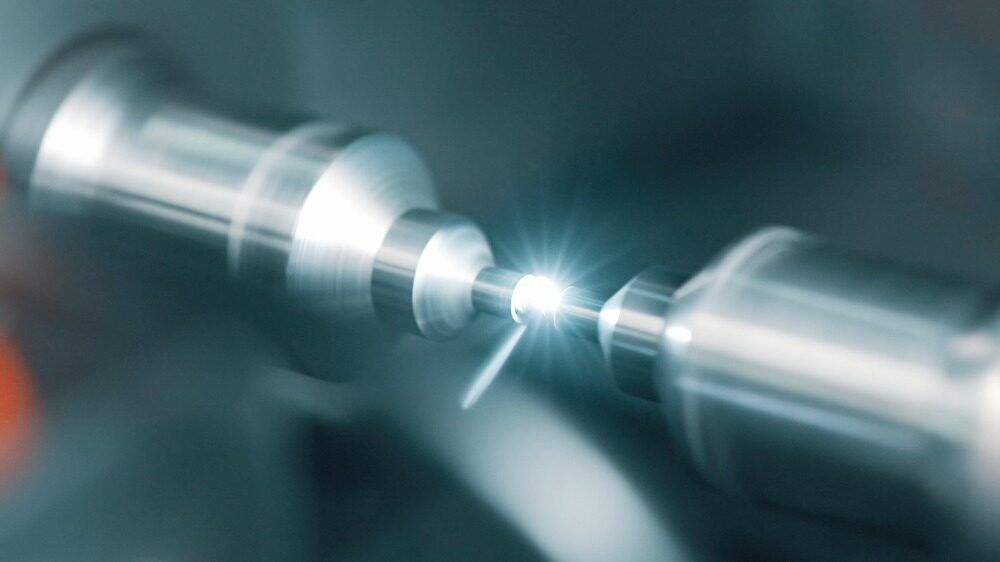

A laser scriber is a versatile and highly precise tool used in various industries for scribing, marking, or cutting materials with exceptional accuracy. It utilizes laser technology to create fine, detailed patterns or cuts on a variety of substrates, including glass, ceramics, semiconductors, and metals. Laser scribers are integral in applications such as electronics manufacturing, solar panel production, and precision engineering.

How Does a Laser Scriber Work?

A laser scriber operates by focusing a laser beam onto the surface of the material. The laser heats the material at the point of contact, causing it to either vaporize or break away, depending on the application. The precision of the laser allows for the creation of intricate patterns, fine lines, or deep cuts without physically contacting the material, reducing the risk of damage or contamination.

Key Features and Benefits

Precision and Accuracy

Laser scribers offer incredibly high precision, making them ideal for applications that require detailed and accurate markings or cuts.

Minimal Contact with Material

Since laser scribers use a non-contact method, they minimize wear and tear on both the tool and the material being processed.

Versatile Material Handling

Laser scribers can work with a wide range of materials, including fragile ones like glass or delicate ceramics, without compromising their structural integrity.

Customization Options

The ability to adjust parameters such as laser power, frequency, and speed means that the process can be tailored for different materials and application needs.

Applications of Laser Scribers

Laser scribers are commonly used in the following industries:

Electronics Manufacturing

For fine patterning of integrated circuits, microchips, and PCB substrates.

Solar Panel Production

To create precise patterns for thin-film or crystalline solar cells.

Glass and Semiconductor Processing

For cutting, scribing, and marking glass or semiconductor wafers used in devices like smartphones and displays.

Inquiry for details

For detailed equipment specifications, functions, or sample processing inquiries, please use the inquiry button located at the top right.