Promotion Movie

The substrate material is mainly alumina ceramic.

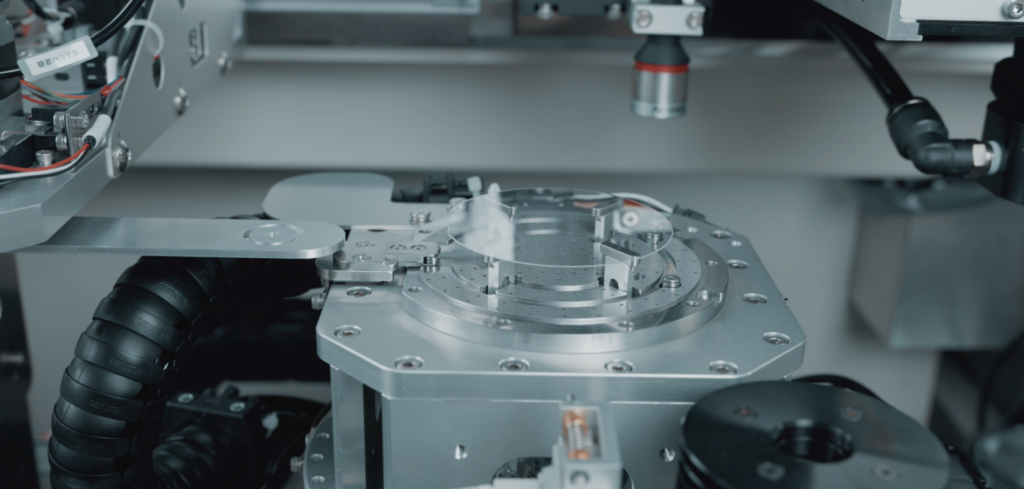

Target work size is 50mm x 60mm and 60mm x 70mm

*We can also accommodate requests for other sizes.

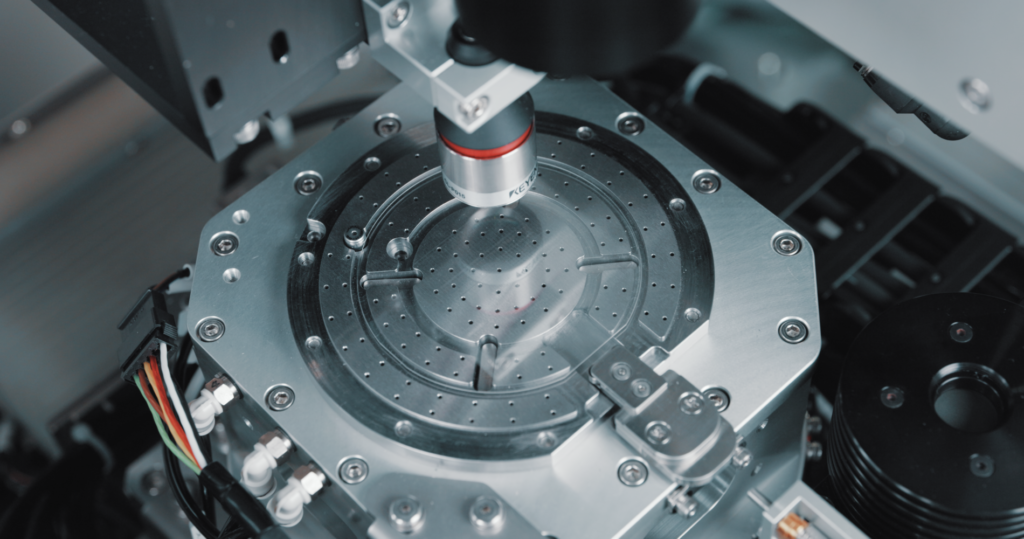

The machine is equipped with a machining position alignment function, an automatic machining height control function, and a front-to-back alignment function.

General Specifications

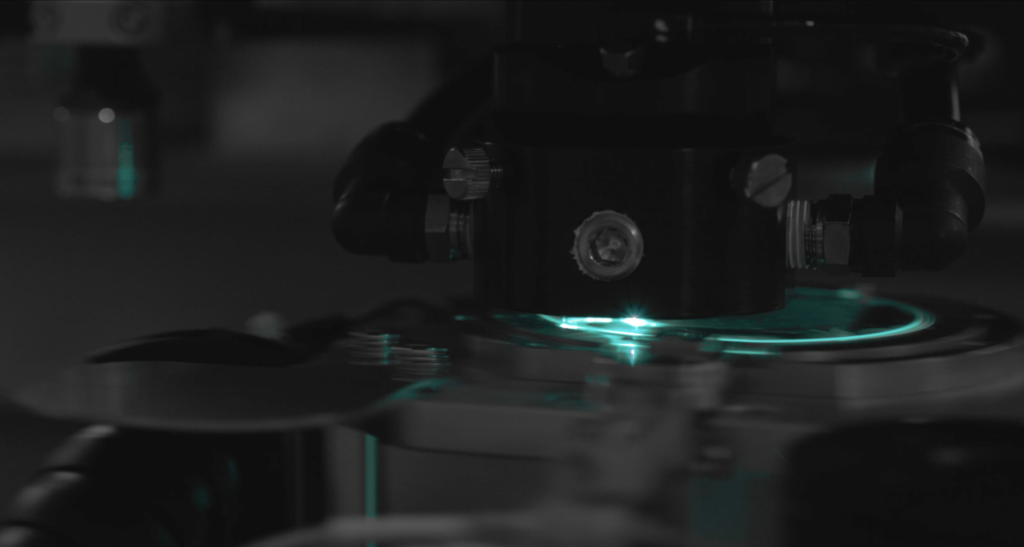

| Laser | Oscillator: Fb LASER Wavelength: 1.08 μm ±10 μ Oscillation Mode: TEM00 mode Average Output Power: 200 W (in CW mode) Minimum Pulse Width: 5 μs Maximum Frequency: 50 kHz |

|---|---|

| Dimensions & Weight (Excluding maintenance space) |

Main Unit: Approx. 1500 mm (W) × 840 mm (D) × 1380 mm (H), Weight: 640 kg Exhaust Pump: Approx. 550 mm (W) × 410 mm (D) × 602 mm (H) |

| Applicable Substrate Size | Substrate Sizes: ① 50 × 60 mm ② 54 × 60 mm ③ 60 × 70 mm Substrate Thickness: 0.09 ~ 0.6 mm Note: To use substrates ① to ③, component replacement is required. For substrates thinner than 100 μm, please consult separately. |

| XY stage | ⚫ XY Stage Travel Range: 250 mm (X) × 145 mm (Y) Travel Speed: 500 mm/sec (Max) Drive Mechanism: Linear Motor Position Offset (Top/Bottom): +8 μm Absolute Position Accuracy: +6 μm Feed Pitch Accuracy: ±6 μm Repeatability: ±2 μm Resolution: ±1 μm or less ● Work Surface Substrate Attachment: Vacuum suction method Number of Substrates: 1 Flatness Accuracy: +8 μm Stage Surface: Both sides observable Material: SUS (Stainless Steel) |

| Processing Optics | Adding Lens: f = 60 mm, BEX Lens Magnification ×2 Camera: 2 units of CCD monochrome cameras Monitor Display: 17-inch touch panel type Focal Position (Z): Stepper motor control (1 μm/step) |

| loader/unloader | Magazine Height: 120 mm (MAX) Magazine Stack: Standard 2 units (1 for supply, 1 for storage) Note: Additional units are available as an option. |

| Power Supply Voltage | Power Supply: AC 200 V ±20 V, Single-phase, 50/60 Hz Air Supply: Pressure 0.5 MPa to 0.6 MPa, Flow rate 40 NL/min |

Understanding Laser Scribers

A laser scriber is a highly adaptable and precise device used across several industries for tasks such as scribing, engraving, or cutting materials with remarkable accuracy. It employs laser technology to create intricate patterns or cuts on materials like glass, ceramics, semiconductors, and metals. Laser scribers are essential in fields like electronics assembly, solar energy production, and advanced engineering.

How Does a Laser Scriber Operate?

A laser scriber works by directing a focused laser beam onto the surface of a material. The intense heat from the laser causes the material to either vaporize or fracture, depending on the desired outcome. This process allows for the creation of highly detailed patterns, fine lines, or deep grooves without direct contact with the material, minimizing potential damage or contamination.

Main Features and Advantages

High Precision and Exactness: Laser scribers are known for their exceptional accuracy, making them perfect for tasks that demand intricate details and precise cuts or markings.

Non-contact Process: As laser scribers work without touching the material directly, they reduce wear and tear on both the device and the item being processed.

Wide Material Compatibility: These tools are capable of working with a broad range of materials, including fragile ones like glass or fine ceramics, while maintaining their structural integrity.

Adjustable Settings: The ability to fine-tune parameters like laser intensity, frequency, and speed enables the process to be optimized for different materials and specific applications.

Common Uses for Laser Scribers

Laser scribers are predominantly used in the following sectors:

Electronics Manufacturing: For precise patterning on microchips, integrated circuits, and printed circuit boards.

Solar Energy Industry: For accurate patterning of thin-film or crystalline silicon solar panels.

Glass and Semiconductor Fabrication: Used for cutting, scribing, and marking glass or semiconductor wafers that are crucial in products like smartphones and display screens.

Inquiry for details

For detailed equipment specifications, functions, or sample processing inquiries, please use the inquiry button located at the top right.