What is Stealth Dicing™︎?

Stealth Dicing Technology focuses laser light of a wavelength that is transparent to the target material, concentrating it within the wafer to form a starting point for division (modified layer, hereafter referred to as the “SD layer”). After forming the SD layer, external stress is applied to the wafer to fragment it into smaller pieces. The process consists of two main stages: the “Laser Irradiation Process,” where the SD layer is created within the wafer, and the “Expand Process,” where the wafer is fragmented into smaller pieces.

—Quoted from the Hamamatsu Photonics website

Promotion Movie

Workpieces that can be processed

- Glass

- Sapphire

- SiC

- GaN

- LiTaO3, LiNbO3

- Crystal

What is stealth dicing?

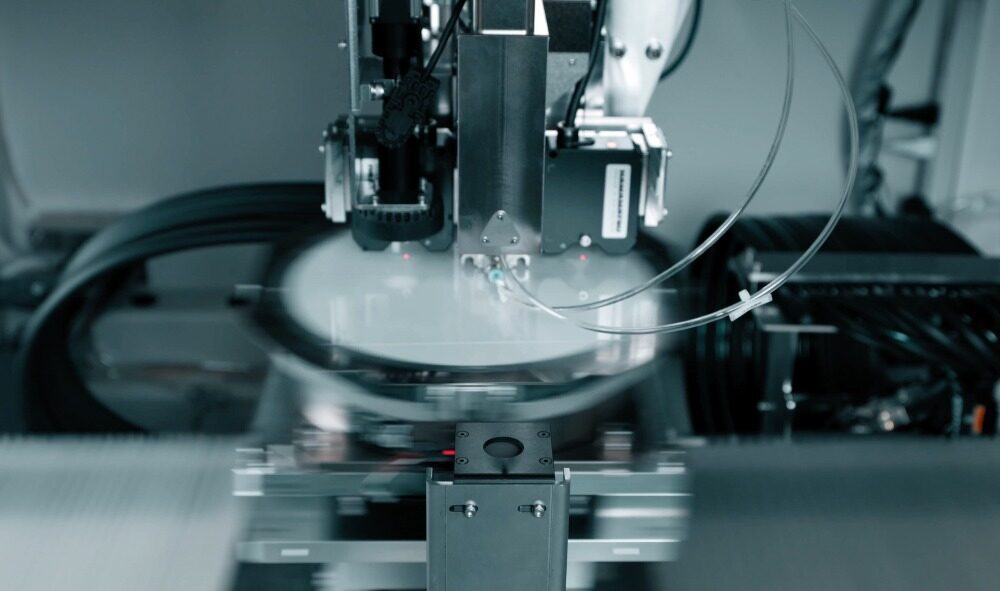

Stealth dicing is a method of forming a modified layer inside a workpiece by focusing a laser beam inside the workpiece and using a tape expander to separate the chip.

General Specifications

| 機構部 | 一般概略仕様 |

|---|---|

| Laser Section | Oscillator: Short-pulse laser oscillator Laser selection available based on the material being processed Optical System: Hamamatsu Photonics 3G-SDE |

| External Dimensions & Weight (Excluding maintenance space) | Main Unit: Approx. 1905 mm (W) × 1802 mm (D) × 1805 mm (H), Weight: Approx. 2700 kg Power Supply & Chiller Rack: Approx. 553 mm (W) × 400 mm (D) × 240 mm (H) |

| Applicable Substrate Size | Substrate Size: Max 160 mm × 160 mm Substrate Thickness: 0.1 mm ~ 0.5 mm |

| Stage Specifications | ● XY Axis Travel Range: 500 mm (X) × 500 mm (Y) Movement Speed: 1000 mm/sec (Max) Drive Mechanism: Linear motor Absolute Position Accuracy: X-axis: 8 μm, Y-axis: 7 μm Repeatability: ±1 μm Resolution: ±0.5 μm ● Z Axis Travel Range: Max 8 mm Movement Speed: 1 mm/sec Absolute Position Accuracy: ±0.5 μm ● O Axis Rotation Range: 360° Rotation Speed: Max 90°/sec Absolute Position Accuracy: ±1 μm ● Suction Table Substrate Fixing: Vacuum suction |

| Substrate Transfer Robot | Type: Cylindrical coordinate robot Substrate Clamping Method: Mechanical check Work Detection: Cassette-based work detection function Cassette: For 8-inch substrates |

| Additional features | Camera Alignment: Corrects the tilt of the wafer and the deviation in XY coordinates Output Measurement: Equipped with a power meter |

| Power Supply Voltage | Power Supply: AC 200 V ±20 V, Single-phase, 50/60 kHz Air Supply: Pressure of 0.5 MPa or higher |

Inquiry for details

For detailed equipment specifications, features, or sample processing inquiries, please use the inquiry button located at the top right.